Bryce C

DFW

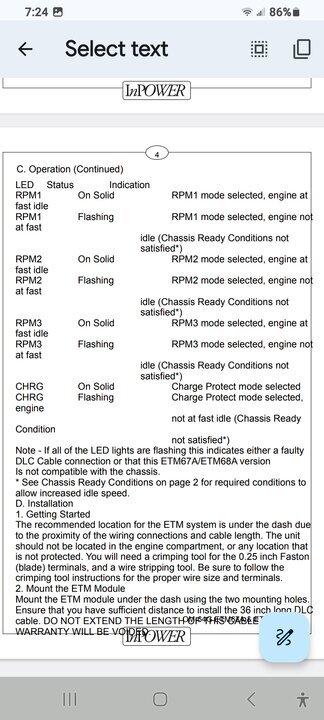

My Hydramaster CDS 4.8 starts at around 1100 rpm on the high setting, and slowly loses rpm and drops to around 600 rpm Weak vacuum, water pump has weak pressure, and my local truckmount service people say they won't work on it. The don't service anything on the engine side of pto setups.

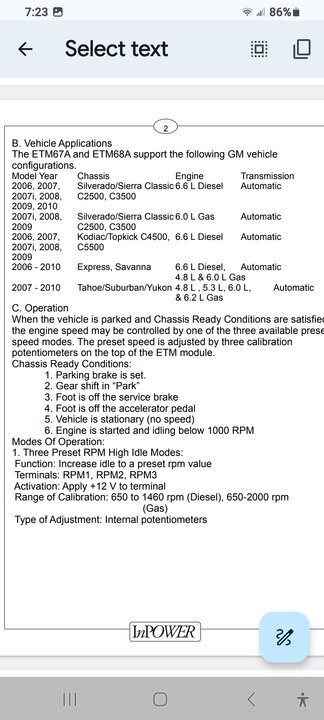

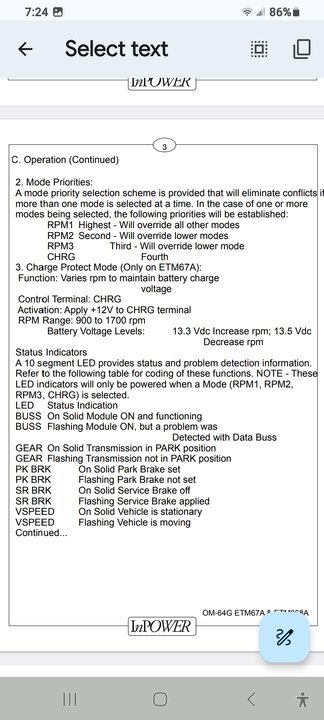

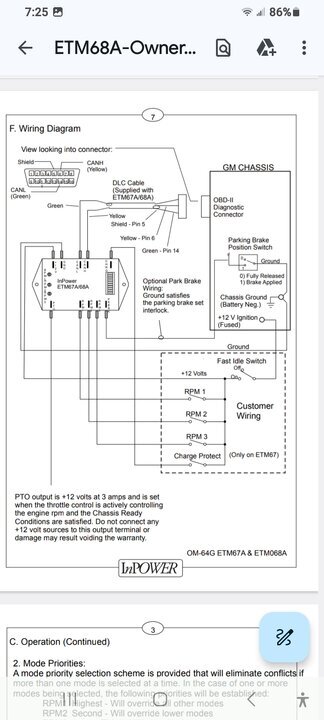

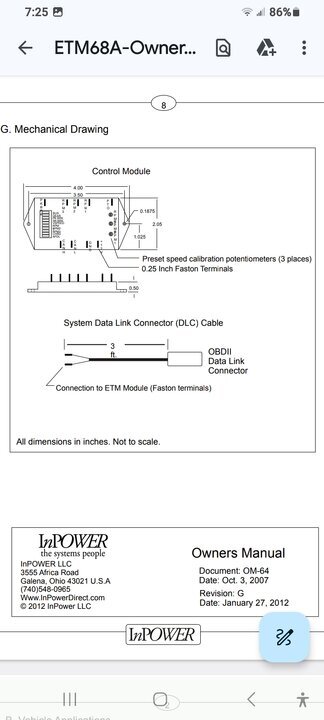

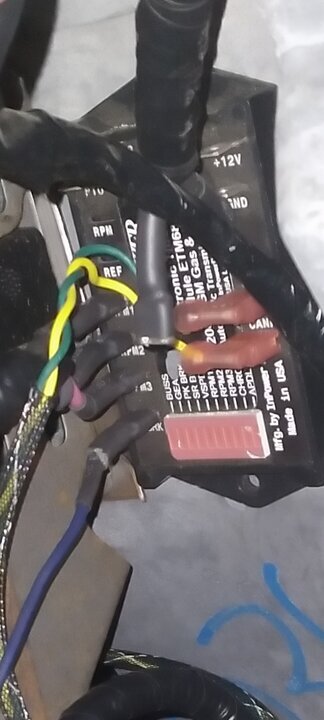

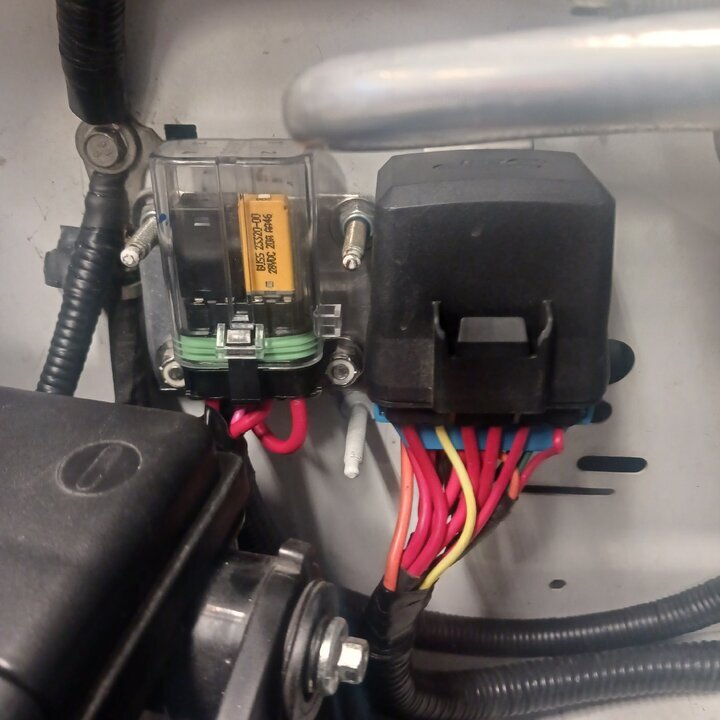

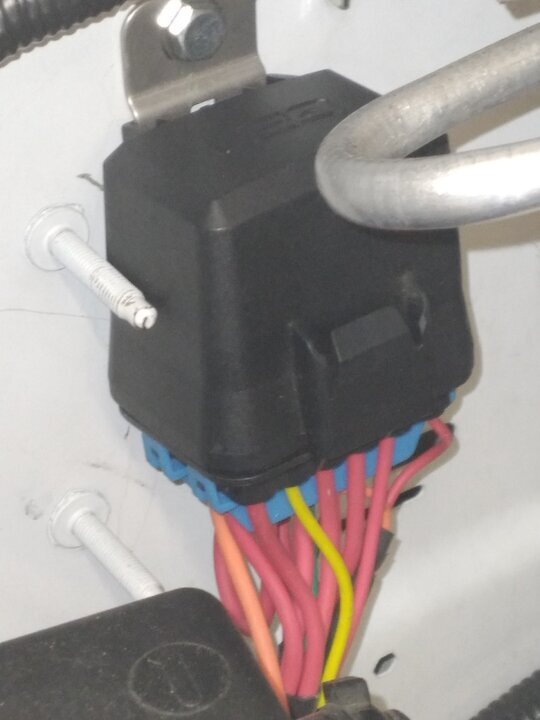

It is a 2013 and doesn't have the adjustable vacuum pods like I read some older models have. There is an electrical pod under the dash but I don't know if anything is adjustable on it. The local truckmount service folks checked for vacuum leaks in the lines that may affect this and didn't find any. They think it is electrical.

I'm waiting to hear back from a friend who is a Hydramaster tech I met at MF this year. For now, do any folks with experience with these CDS systems have any thoughts?

It is a 2013 and doesn't have the adjustable vacuum pods like I read some older models have. There is an electrical pod under the dash but I don't know if anything is adjustable on it. The local truckmount service folks checked for vacuum leaks in the lines that may affect this and didn't find any. They think it is electrical.

I'm waiting to hear back from a friend who is a Hydramaster tech I met at MF this year. For now, do any folks with experience with these CDS systems have any thoughts?

Last edited: